Featured

- Get link

- X

- Other Apps

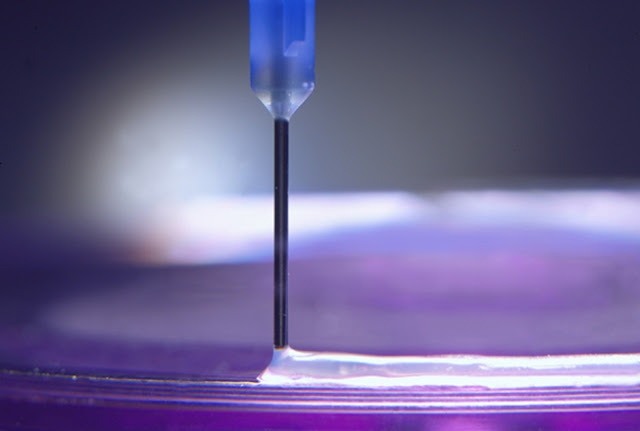

The Benefits of UV curing optical adhesives

Optical engineers often need adhesives to bond components together throughout optical assembly, lens and prism bonding, positioning and solving of optical elements, and fiber optic assembly. Each adhesive has its very own strengths and barriers, that may make it difficult for the engineer to determine which material is exceptional perfect for the venture handy. The selection of an adhesive calls for careful consideration, weighing the homes of the fabric towards the necessities of the software, balanced in opposition to the needs of the technique. Of course, optical transmission and refractive index are often number one considerations, but there are different things to think about.

Properties

To a few quantity, all adhesives shrink in quantity throughout curing. This can reason element pressure and awareness and alignment issues for the duration of processing. To triumph over this, the engineer can opt for a material with low shrinkage. Standard epoxy adhesives generally have a shrinkage of around three to five percent. There are special UV curing optical adhesives that shrink 0.2 to zero.4 percentage at the same time as preserving optical clarity. The hardness and modulus of the cured fabric may be essential to the integrity and overall performance of the shape.

The optical engineer need to also recollect outgassing (the release of unstable materials both at some stage in and after curing) while choosing an adhesive, if condensation of these volatiles on optical surfaces will motive satisfactory troubles.

Curing and managing

The optical engineer ought to consider the method of curing the adhesive and how it will affect the velocity and complexity of the project. UV curing adhesives therapy in a few seconds, which can be beneficial if velocity is a manufacturing requirement. This fast treatment is helpful during alignment or targeting as the adhesive healing procedures quick once the location technique is whole, liberating up complex jigs and furnishings for the following meeting. Two-component optical epoxies take longer to cure than UV-cured adhesives (minutes to days in preference to seconds); they can be extended with warmth, despite the fact that thermal tour can induce pressure in parts all through and after curing.

The viscosity of the adhesive is also a aspect. Will the adhesive be required to fill an opening; wick in a gap; or bridge an opening? If a two-component machine is targeted, mixing will become a technique problem. Special equipment may be required to provide a repeatable homogeneous blend and degassing can be required if the mixing system induces air that turns into an unacceptable artifact in the mild course.

UV curing acrylate adhesives are a popular preference for optical applications because they may be clean to use and offer a quick cure time. For example, low-pressure, low-movement UV-curable optical assembly adhesives, inclusive of those in the Dymax OP range, provide optical engineers options that therapy in seconds even as supplying electricity and clarity. Offering shrinkage as low as 0.1 percentage, 3000 psi excessive tensile power bonding in a single factor, this sort of adhesive is a compelling preference for many optical programs.

Optical adhesives have come a long manner since Canada Balsam and the extensive range of alternatives now to be had can make choosing the proper adhesive for your utility a challenging challenge. By operating with an skilled adhesive supplier, optical engineers could make informed selections about the most appropriate fabric and method for their utility.

Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Uv curing uv curable adhesives Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Deepmaterial Plastic bonding adhesive Curable adhesives Uv curing uv curable adhesives Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive Curable adhesives Deepmaterial Plastic bonding adhesive- Get link

- X

- Other Apps

Popular Posts

How To Make Golf Cart Batteries Last Longer

- Get link

- X

- Other Apps

5 Tips to Extend the Lithium-Ion Battery Life

- Get link

- X

- Other Apps

Comments

Post a Comment